Intro

IMPORTANT: Guide will be updated for Full Release when I can find the time to do so!

A Main Bus is one of the most widely-used factory designs among Factorians for its flexibility and ease-of-use. A well-designed Main Bus can help you build a neat and efficient factory that is able to supply all the products you need.

If you are a beginner to Factorio, or need more generalized help, please see my Factorio Guide here:

http://steamcommunity.com/sharedfiles/filedetails/?id=661582295

In The Beginning...

... there were conveyor belts. And the character saw they that they were good... and that they would help him on his quest to get to end-game.

Starting Out

In the very beginning of the game, you will be using yourself as a transporter to move things between chests to start out the game.

ASAP, you need to build an electric setup, and get electric mining drills going to supply lines of furnaces.

These very first lines of furnaces are the beginning of your new Main Bus.

As soon as you start using conveyor belts, you should be using a Main Bus. Any delay in setting it up will just result in wasted time and effort creating temporary lines.

Structure

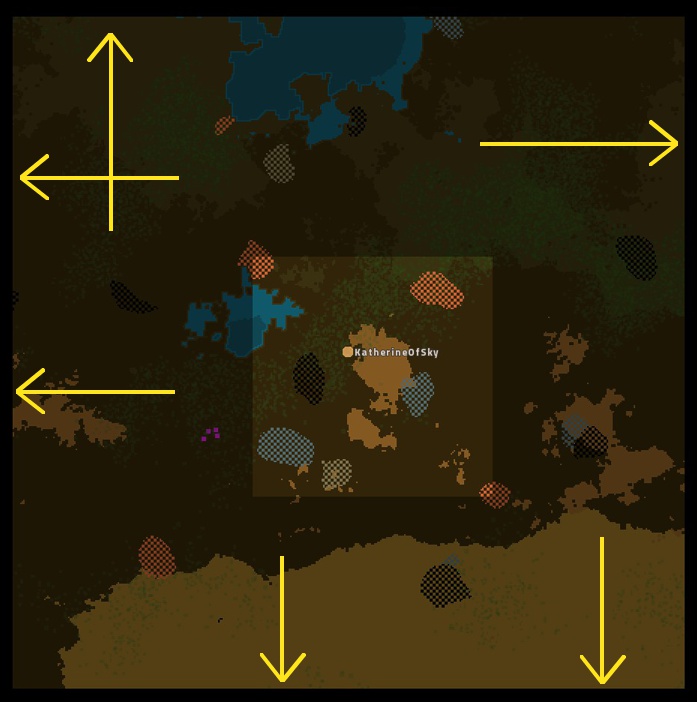

PlanningEven at the earliest stages of the game, you should plan where your main bus will go. You typically want it to go in a straight line horizontally or vertically. (It can also snake around lakes, but making corners with the large width of the belt takes a large amount of space).

Looking at your map, choose a wide open place with expandabiity in at least one direction, away from ores/ore processing facilities.

Yellow arrows all indicate possible starting locations and directions for your Main Bus. Choose one carefully, so you will have plenty of room to expand.

ProductsEach of these is essential to your main bus design:

Iron Plates x4 (recommend x8)

Copper Plates x4 (recommend x8)

Steel Plates x1 (recommend x2)

Green Circuits x2 (recommend x4)

Red Circuits (Advanced Circuits) x1 (recommend x2)

Blue Circuits (Processing Units) x1

Plastic x1 (recommend x2)

Batteries x1

Stone Bricks + Stone x1

Coal x1

Lubricant (via pipe)

Sulfuric Acid (via pipe)

"x" numbers indicate number of belts for a "small" sized factory. Recommended numbers are for a "regular" factory needing good throughput for a decent rocket launching.

The rest of this guide is written using the recommended numbers to illustrate examples more fully.

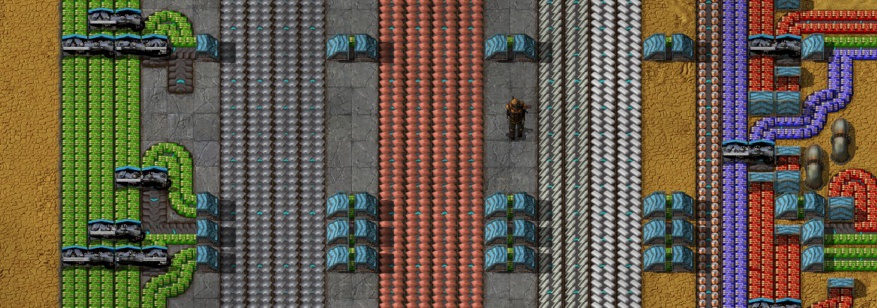

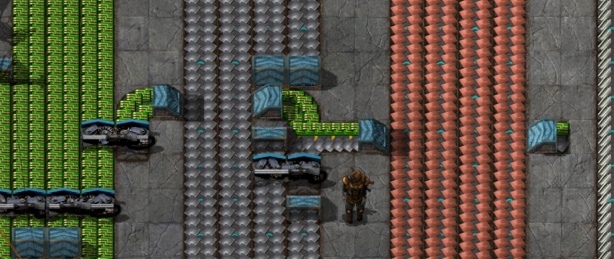

A rainbow of belts will provide excellent throughput for your factory.

Belt Structure

There are a couple of different structures you can use for your main bus design. Some people put all lanes together, but I highly recommend a structure of

4 belts, 2 spaces, 4 belts, 2 spaces, and so on, with the piped products on one side.

This structure enables you to easily split from the side of one belt group, leaves room to put down an underground belt, while being compact enough to allow undergrounds to cross unimpeded.

Leave spaces between groups of belts to allow for undergrounds to pass though. Remember to add pipes for the liquid component of the Bus!

There's no need to build all-the-belts initially, just make a placeholder with a single square of belts for each line... planning so you know how far to place your assemblers from the line.

You can mark each lane with a piece of material (if you have one on you). To drop material, hold it in your hand, and then press Z to drop. Aim for the belt!

Markers on the belts help you remember what needs to go where.

Feeding The Bus

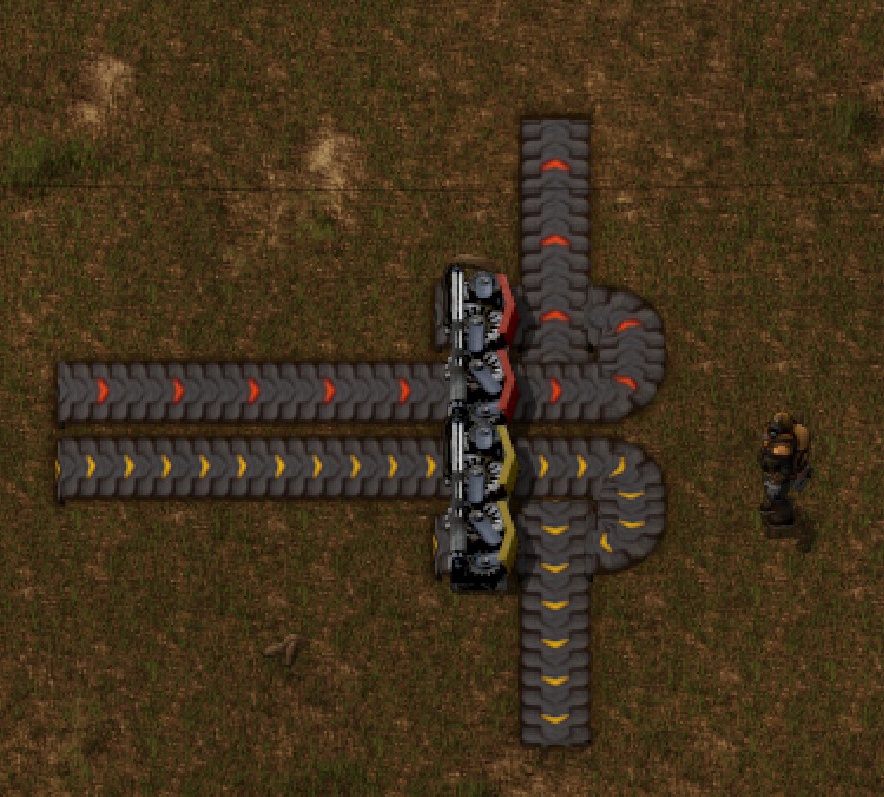

Belt BalancersBefore it is put onto the line, a belt should be balanced to even it out as much as possible. Use any of the following balancers to even out lanes before they get to the Main Bus. (I typically put them right at the outlet of the furnace setup.)

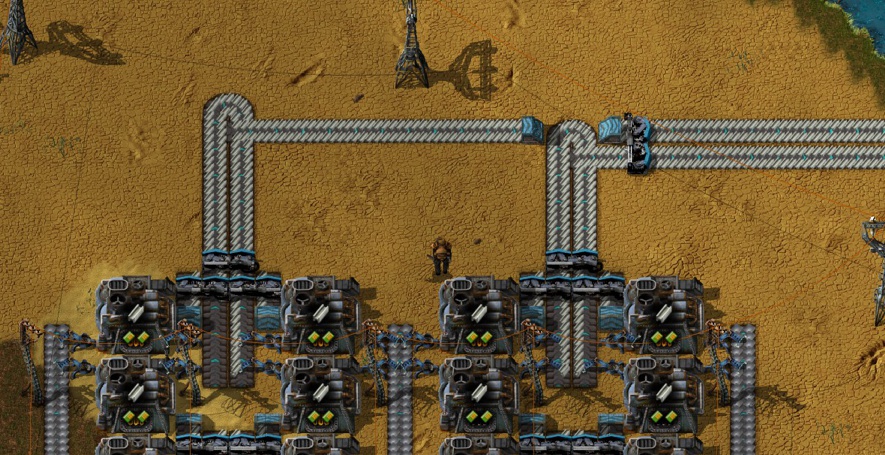

Corner balancer. Belt colors are for contrast.

Straight/in-line balancer.

Steel is balanced each belt before it is mixed and then goes to the Main Bus.

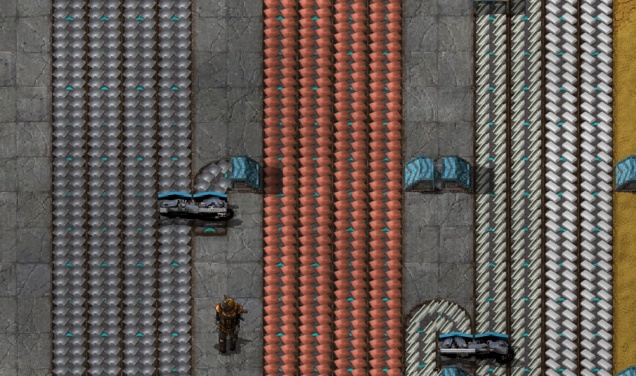

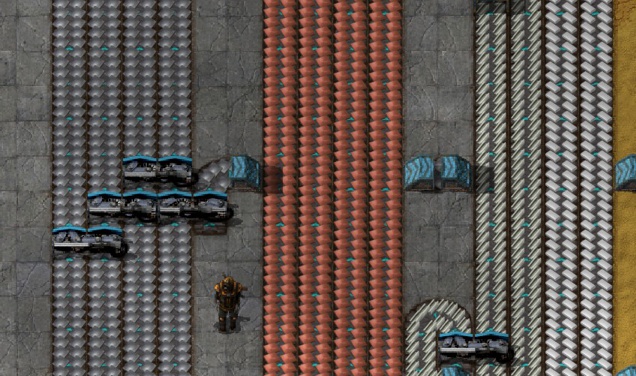

Lane BalancersOnce on the Main Bus, if you have 2 lanes, you can use a regular splitter to balance products. However, if you have 4 or more lanes, you will want to use a better structure than a spam of splitters to equally divide the items between belts.

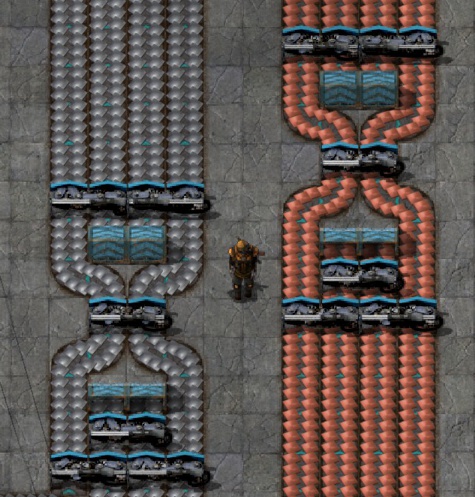

Here's my favorite 4-lane splitter.:

Build diagram of a very efficient 4 lane splitter.

4-lane splitters in practice.

More balancers can be found on this Reddit Post. https://www.reddit.com/r/factorio/comments/4d3per/belt_balancer_compendium/

Plenty of Lanes, but Not Enough Production... Yet!You will start feeding the bus initially from furnaces making iron & copper plates. As you begin to populate your bus with products, make sure you use splitters to distribute some of each to ALL intended belts.

E.g. even if you only have 1 belt of copper plates coming into the bus, use a splitter to spread them over the 4 lanes allocated to them. This enables you to use both sides of a 4-wide lane of products to split off from.

You can easily add in new lanes of plates, (for throughput), when you are more able to build them. (See Green Circuit picture below).

Introducing Intermediate ProductsObviously everything can't be at the beginning of the Bus: intermediate products need other intermediate products to be crafted.

Adding these in is simple when you have already budgeted space for them. At the end of each assembly line, just make sure you balance the belts before putting them on the line.

Adding in green circuits is easy when you've already planned a space for it. Early-game, you'll have only 1 belt's worth. Split it across all 4 belts allocated until you can build more production.

You can even add products mid-line, even when their contents goes in the opposite direction:

Using a splitter to allow Advanced (Red) Circuits to go both directions on the Bus.

Adding Liquids

Most liquids can stay around the oil processing area. However, I like to add these to the Main Bus:

Lubricant: Used in making Electric Engines & Express (blue) level belts, splitters and undergrounds.

Sulfuric Acid: Used for both batteries and Processing Units (Blue Circuits).

I run these pipes on one side of my bus, 2 spaces away from the main conveyor belts.

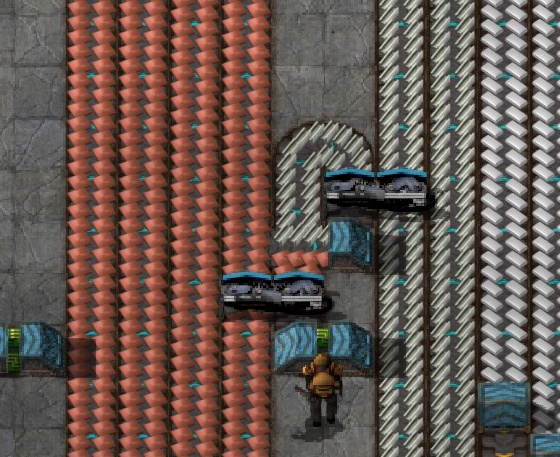

Pulling From The Bus

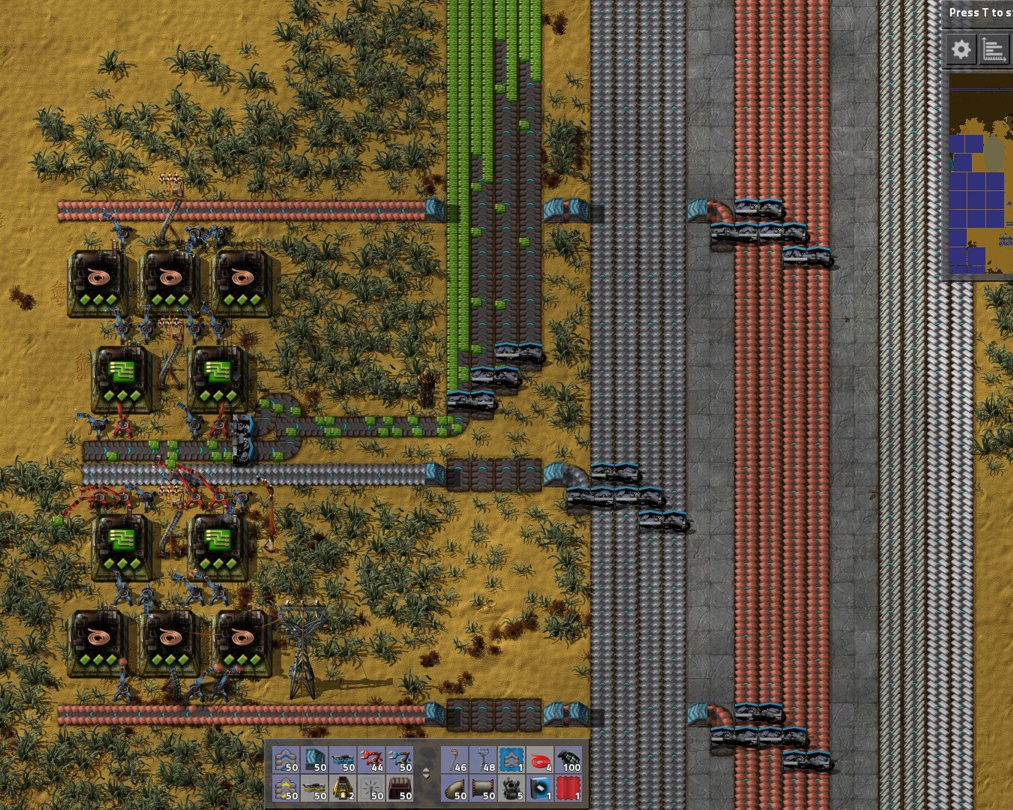

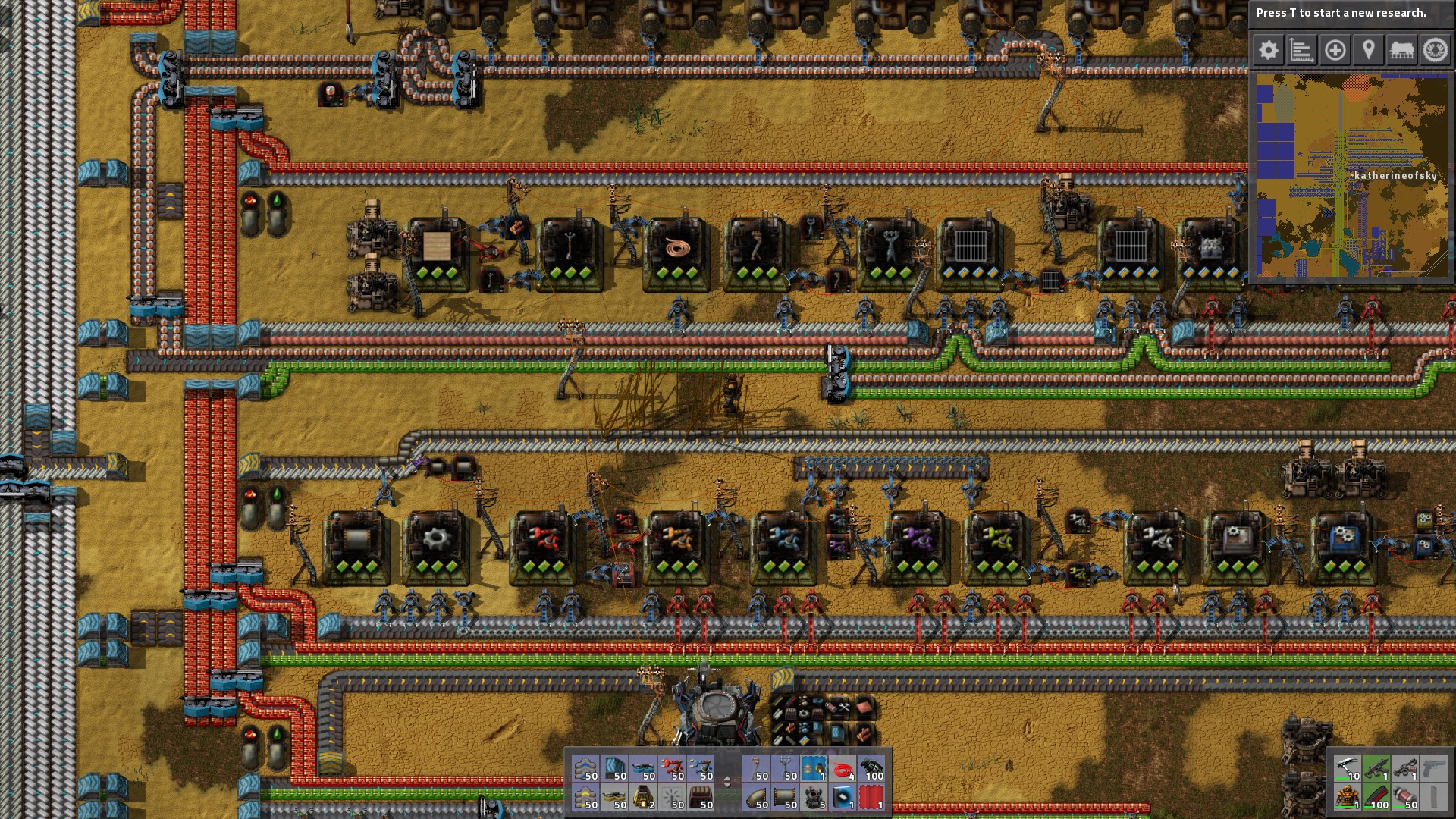

Assembly lines are best placed so that they run perpendicular to the Main Bus. This allows for expanability of systems, and easy pulling from the Bus.

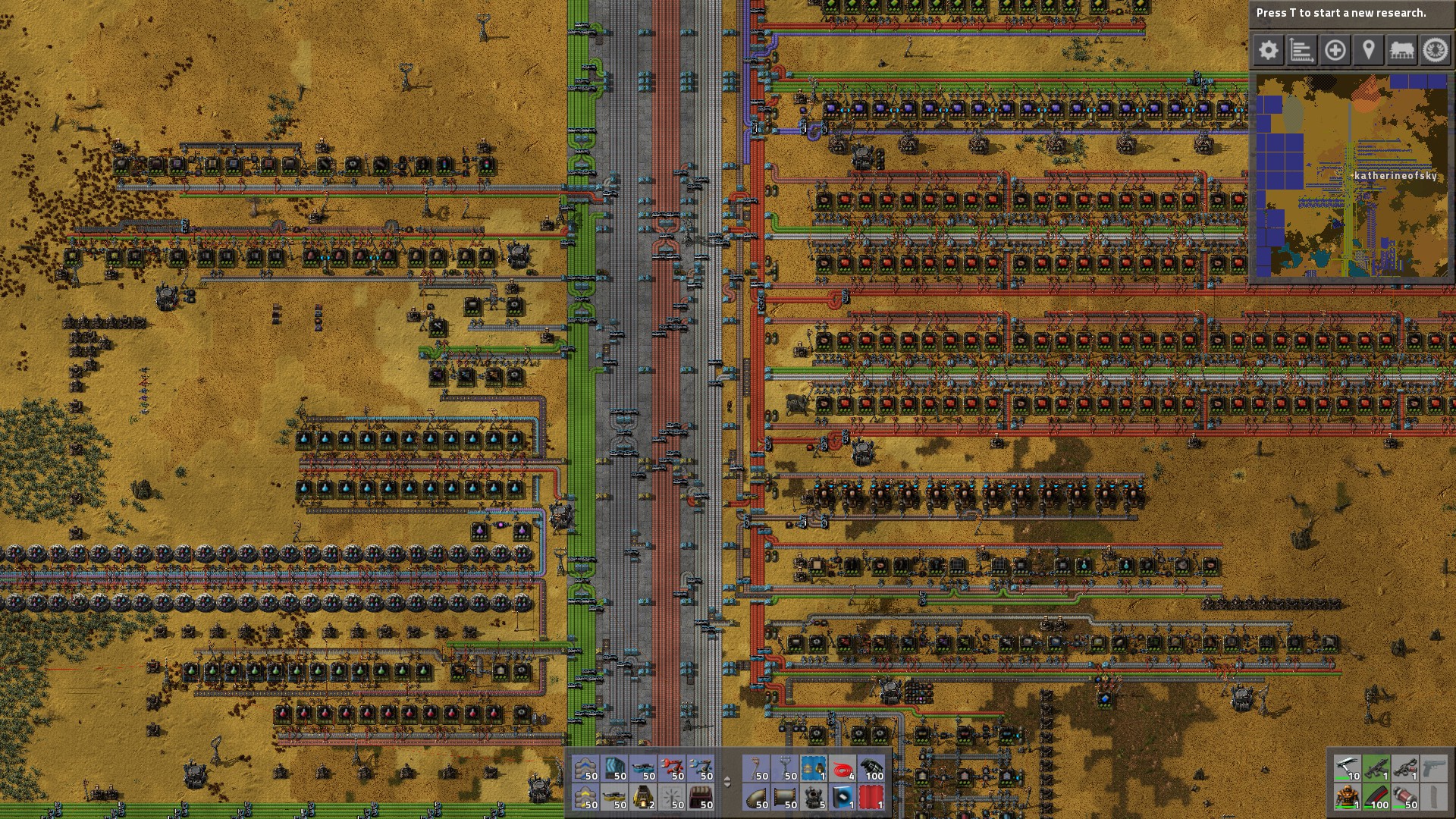

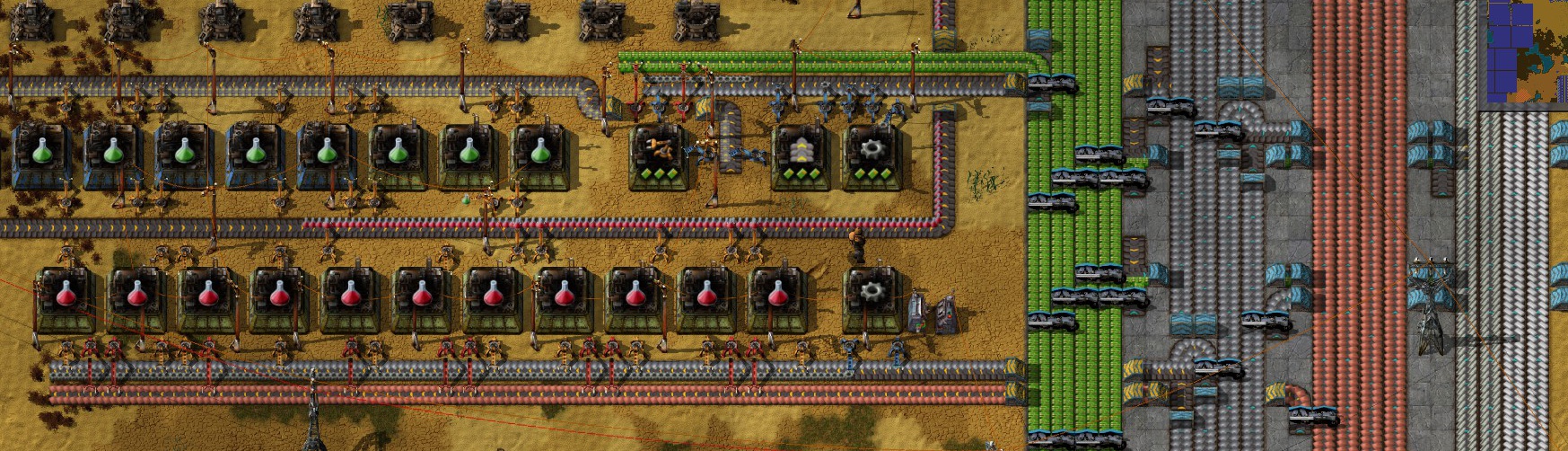

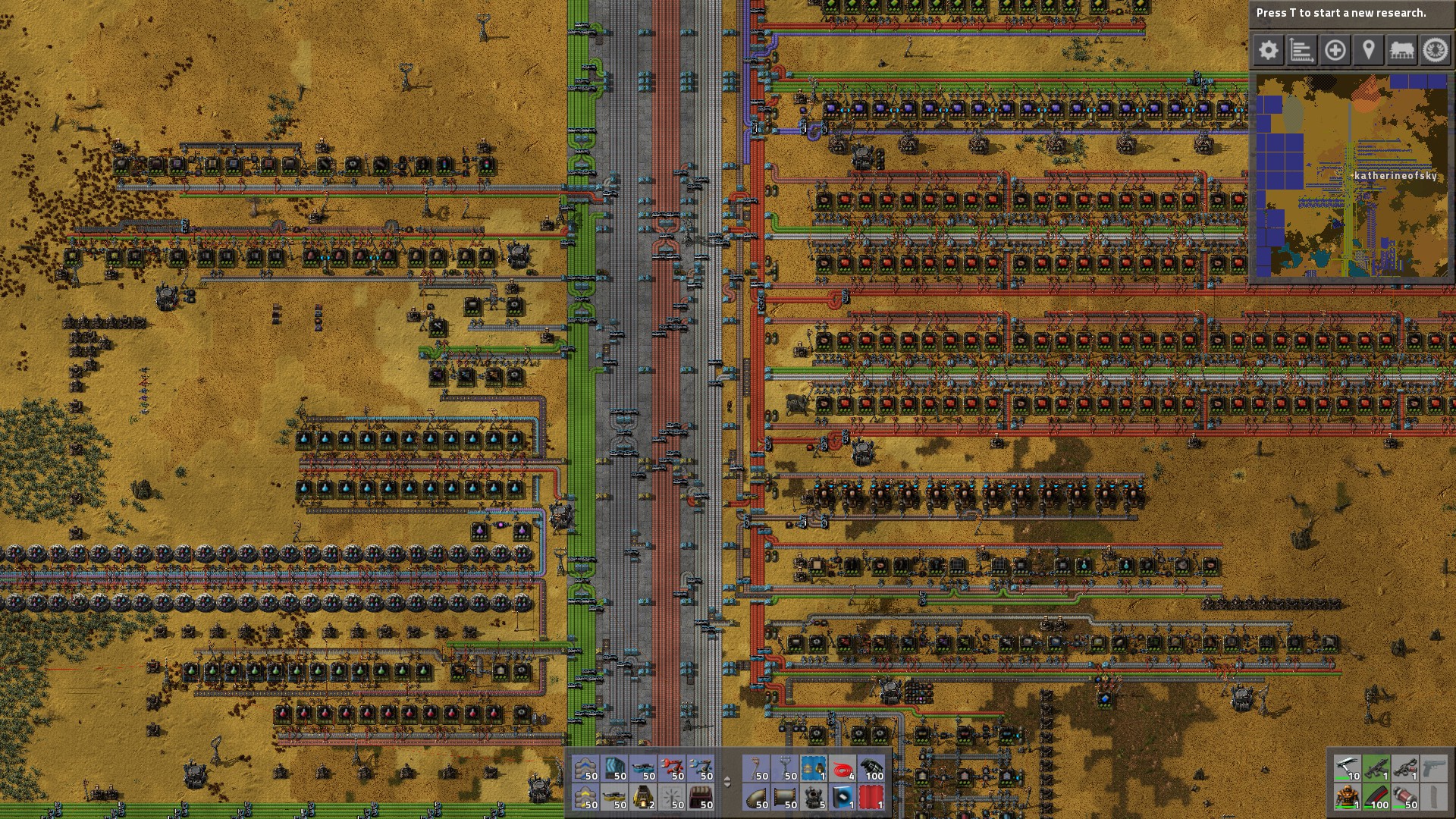

This bus runs North/South and Assembly lines come off and expand to the East and West.

Many different products share similar intermediate product needs, so they can share input lines. Note: don't place too many on the same line if you need large numbers of a single product -- they might cause a shortage of materials for other products down the line!

Pulls from the Main Bus can service a large number of individual products when they share the same inputs.

Full Lane Split OffTo bring a single material down the line, simply put a splitter on the line, then use undergrounds to transport it to the area you need.

First stage of a full belt split off. Remember to re-balance the Main Bus lines. (Read the Re-balance section that follows.)

If you are pulling from a middle lane in the bus, make sure to use undergrounds to allow the rest of the products on their way.

Pulling from a single belt in the middle of a 4 belt group. Make sure to convey the other products with undergrounds around the split.

I like to leave at least 3 tiles of space along the belt-sides of assembly lines -- 1 space for inserters, 2 for belts. I like to put chests between the assemblers so they can transport intermediaries up the line.

Leaving spaces between assembly lines allows for expansion. Chests are in between the factories, allowing for efficient space usage.

Two-material SplitThe vast majority of your split-offs from the Main Bus will be a single belt that carries 2 lanes of different materials. It's a space-saving, efficient design, and allows you to provide up to 8 different intermediate products with standard inserter setups. (2 belts on each side of the inserter lines, carrying 2 products each, fed into machines by regular and long-handed inserters.

You are aiming to create a structure like this: two belts feeding into a single lane, forming a T where the belts meet. Each belt can only drop on to the side when placed this way.

The easiest way to do a two-material split off is to start with the position of the belt near the assembler, and work backwards.

Bring the belt to the target lane, then split off, making sure you make the T-junction BEFORE connecting it to ensure that product fills only a single side of the belt.

Next, work back from the second side of the T-junction to get the second material.

Balance After you split off to the side, you will need to balance the belts again to feed more back to the lane you just took from.

On a two-belt line, (like steel or plastic), use a regular splitter.

On a 4 belt line, you need to make sure the furthest belt from the split can feed into the edge you split from. Therefore, use 3 splitters to divert resources back to that lane.

Original Split Off

Adding in splitters

Arrows show direction of product movement. After the split off at lane 4, splitters allow movement of product to go all the way from lane 1 to lane 4, replenishing product on all lines.

If your lanes are getting chronically unbalanced, consider putting in a proper 4 lane belt balancer, which splits products equally:

A proper 4 lane belt balancer, (on iron), which splits products equally next to the space-saving solution (copper) which is a stop-gap solution when you have less space.

Another example of splitting two products off the Main Bus:

Splitting Off

Adding the replenishment splitters

Say No to Underground Splits!If you use the "quick & dirty" method of using an underground belt to draw from the split, be aware that you will ONLY pull from one half of the belt, which causes serious balance problems, as the splitter will not compensate.

Using an underground belt for splitting off may seem like a quick & easy solution, but because it only pulls from one lane of the feeding belt, it can cause major balance & throughput issues.

...Err Sometimes Undergrounds are UsefulThe only good time to use an underground belt on a line is when you want to separate two products from a belt and want full throughput easily. (A single filter inserter won't fill the belt.)

Separating 1 lane from the belt:

Separating both lanes:

Example Assembly Lines

Here are some Assembly line examples to get you started:

Red & Green ScienceRed Science needs Gears & Copper to craft.

Place Assemblers: 1 crafting Iron Gear Wheels, 6-8 making Red Science.

Place 2 rows of belts along the assemblers. Place another belt along the output side of the assemblers.

Place 2 fast inserters in, and 1 fast inserter going out of the Gear Wheel assembler. Place a regular inserter and a long armed inserter to feed each Science assembler.

For the belt furthest from the assembler, split off copper plates.

For the belt close to the assembler, split off half a lane of iron plates. Neatness matters! Make sure the empty side is across from the inserter! (As shown).

Green Science needs belts and inserters to craft.

Place Assemblers: 1 crafting Iron Gear Wheels, 1 each for belts and assemblers, then 8-10 for Green Science. Place these one tile away from the Red Science output belt. Green Science will share the other side.

Place 2 rows of belts along the gear, inserter, and belt assemblers, and place the snaking belt that leads to the Green Science assemblers as per screenshot below.

Place inserters as per screenshot -- only inserters need long-arms.

For the belt furthest from the assembler, split off green circuits.

For the belt close to the assembler, split off half a lane of iron plates. Neatness matters! Make sure the empty side is across from the inserter! (As shown).

Done! Two science packs made efficiently and traveling together on the same belt!

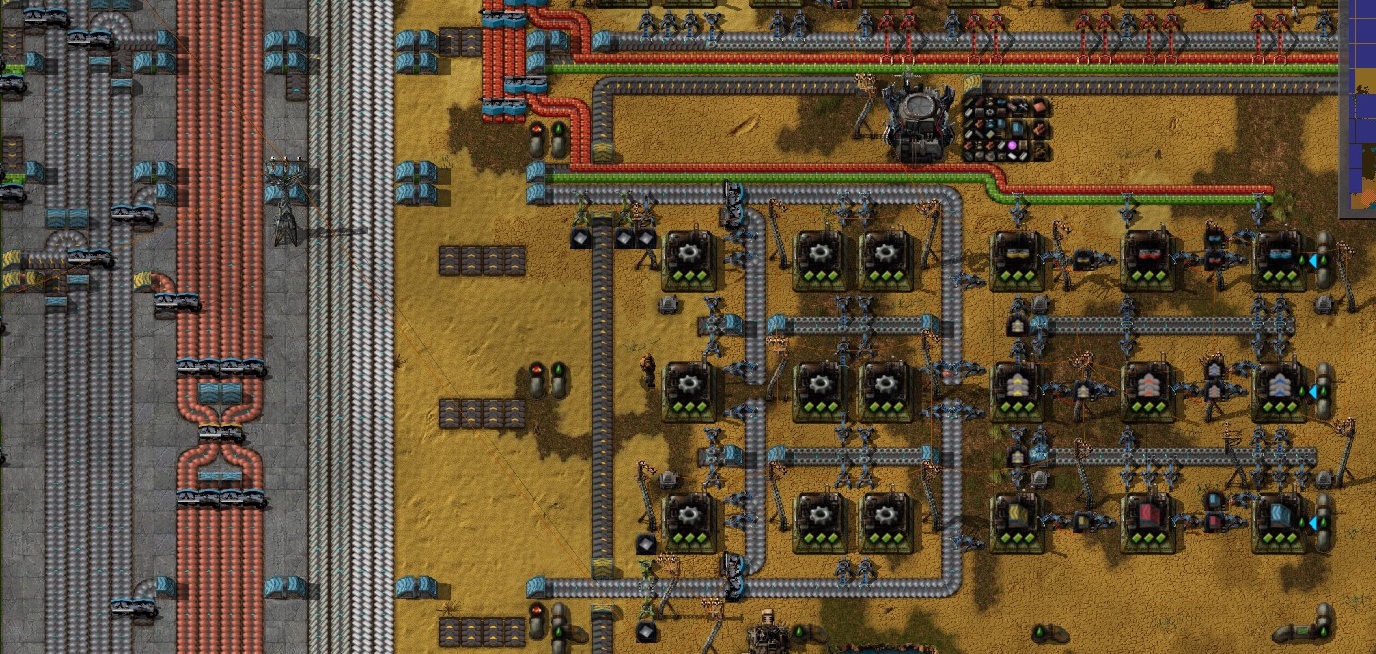

Belt ArrayFor this very fast and efficient belt array, construct as shown:

Place assemblers in a grid-like pattern as shown, adding belts, inserters, and power poles.

Chests between each belt structure move items along as well as providing a collection place for pickup. These start out as iron chests, upgrade to Passive Providers, then to Requesters as earlier belts are phased out.

Split off iron in two places (for throughput), and a half-belt of green circuits. If you don't have red circuits yet, don't worry -- you're just planning for the future!

Make sure to leave room for a lubricant pipe to feed the blue belt assemblers

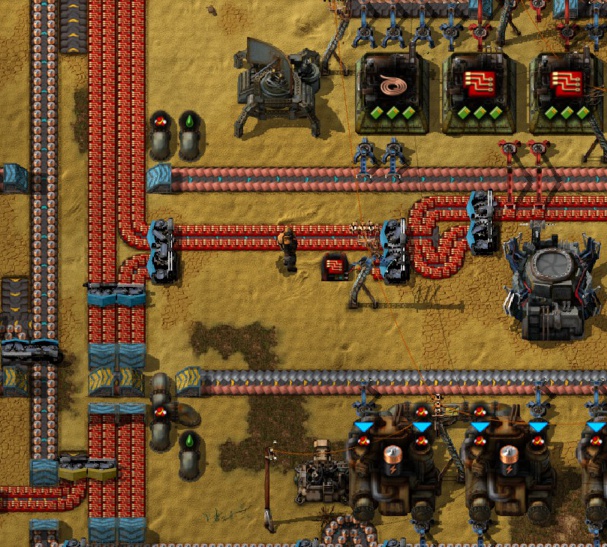

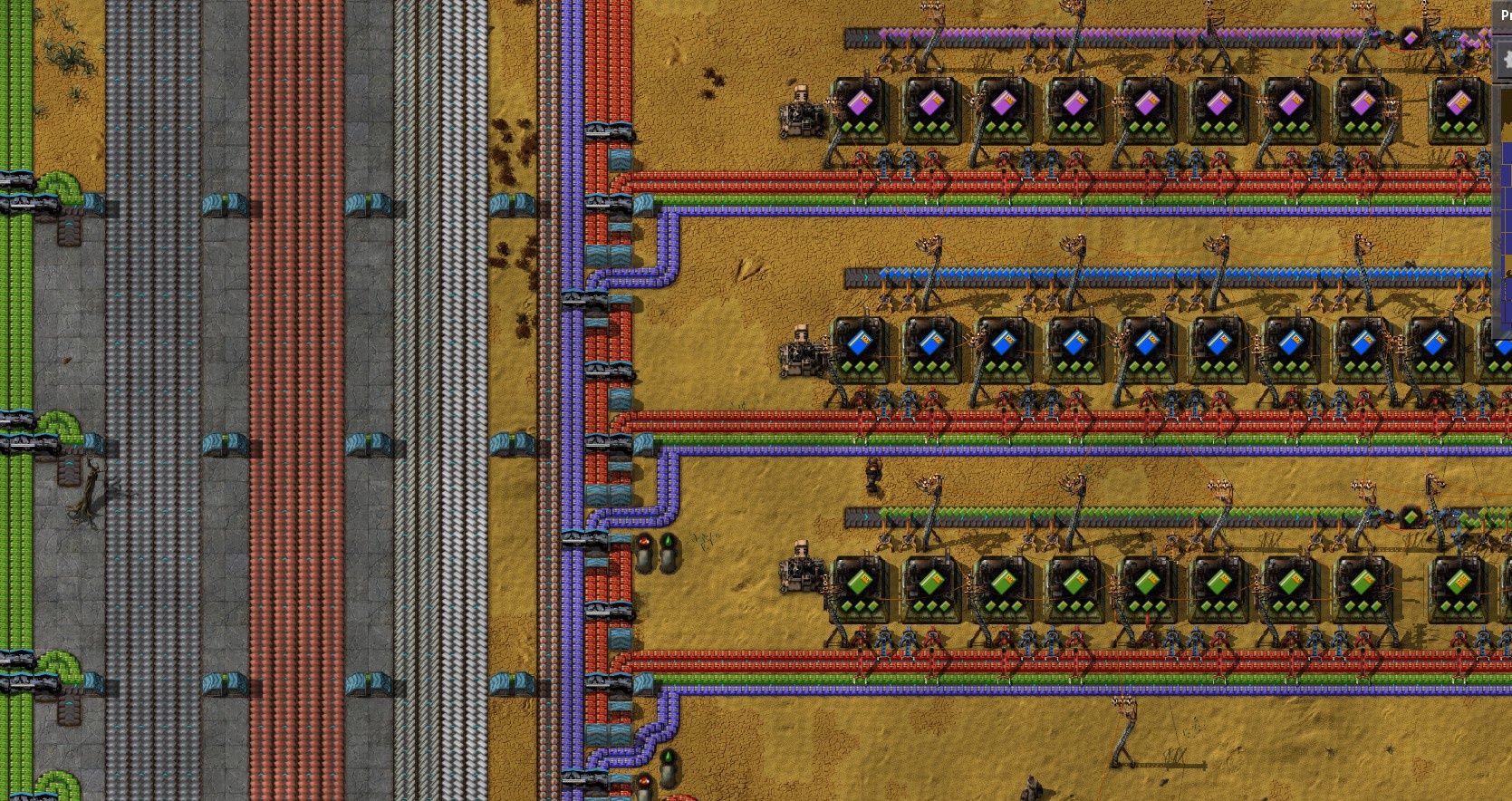

ModulesModules are relatively easy to set up.

Split off a full belt of red circuits to go closest to the assemblers, since they are needed in highest quantity.

Green & blue circuits share a line going in.

Maintaining The Bus

Make sure to re-balance belts after you split from them.

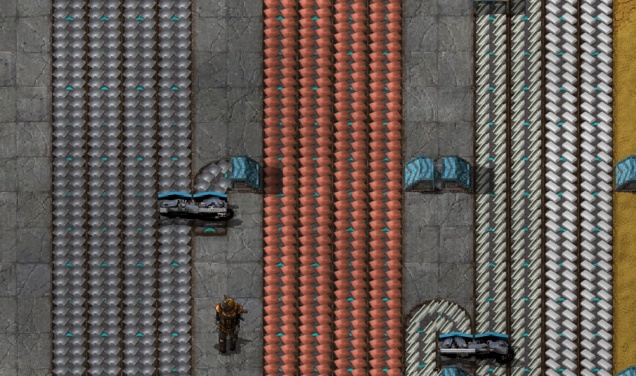

Upgrade belts when more throughput is needed. (I normally skip red belts and go straight to blue to save myself the annoyance of replacing the bus 2 times).

The easiest way to upgrade belts is simply run along the line, holding down the mouse button to place belts on top of existing ones. You can replace splitters and undergrounds similarly by just placing upgraded versions on top of the old, (without the need to deconstruct them).

When you get robots, you can easily extend the bus with blueprints.

Add more production to fill your belts with intermediate products: Copper & Iron Plate, Steel, Green Circuits, etc.

Place Concrete or Stone Brick under a couple lanes of your bus & in one of the spaces between lanes (at a minimum) since it gives you a speed boost when running.

When you find yourself needing an extra component that is used for very few items, (like stone, stone bricks, or coal), either run a line to the side of the main bus, ending it at the assemblers, or carry the materials in via robots & requester chests.

Science & The Bus

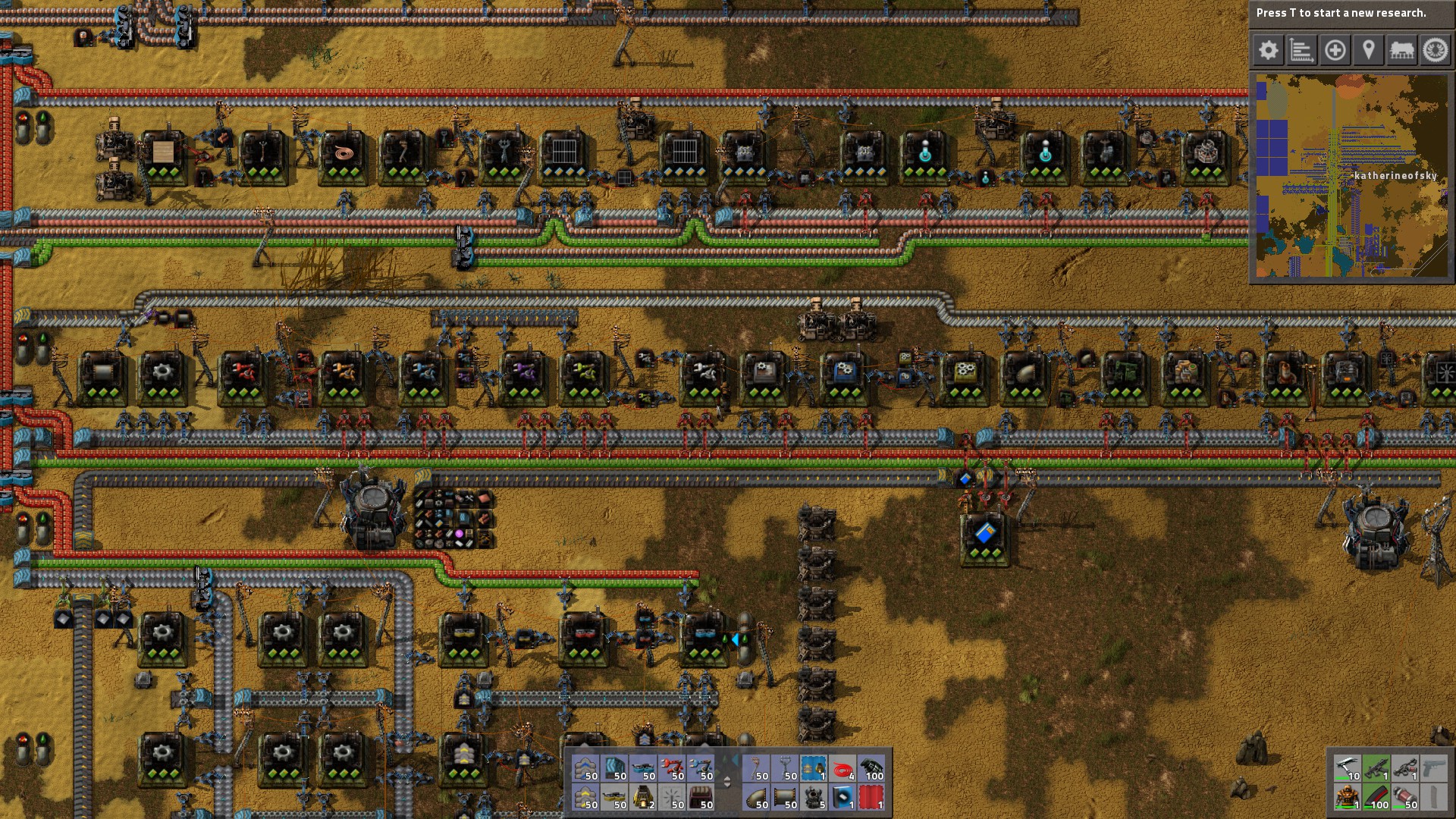

Science pack production can efficiently pull off of the main bus to have an expandable system.

In this setup, I have 64 labs benefiting from serious Main Bus throughput. As an aside, I also have the entire area wired separately from the factory and connected with a Power Switch, so I can turn it off when research is exhausted.

Moving Off The Bus

When your need for materials becomes too great, you may want to consider moving some production OFF of the bus and feeding it in from other locations. Some people build these assemblies off to the side, or transport these products by train as they run out of space near the beginnings of their factory.

In particular, I feed my green circuit assembly with 3 belts of iron plates + 4 belts of copper plates. These are separate from the lines on the Main Bus.

Screenshot Examples

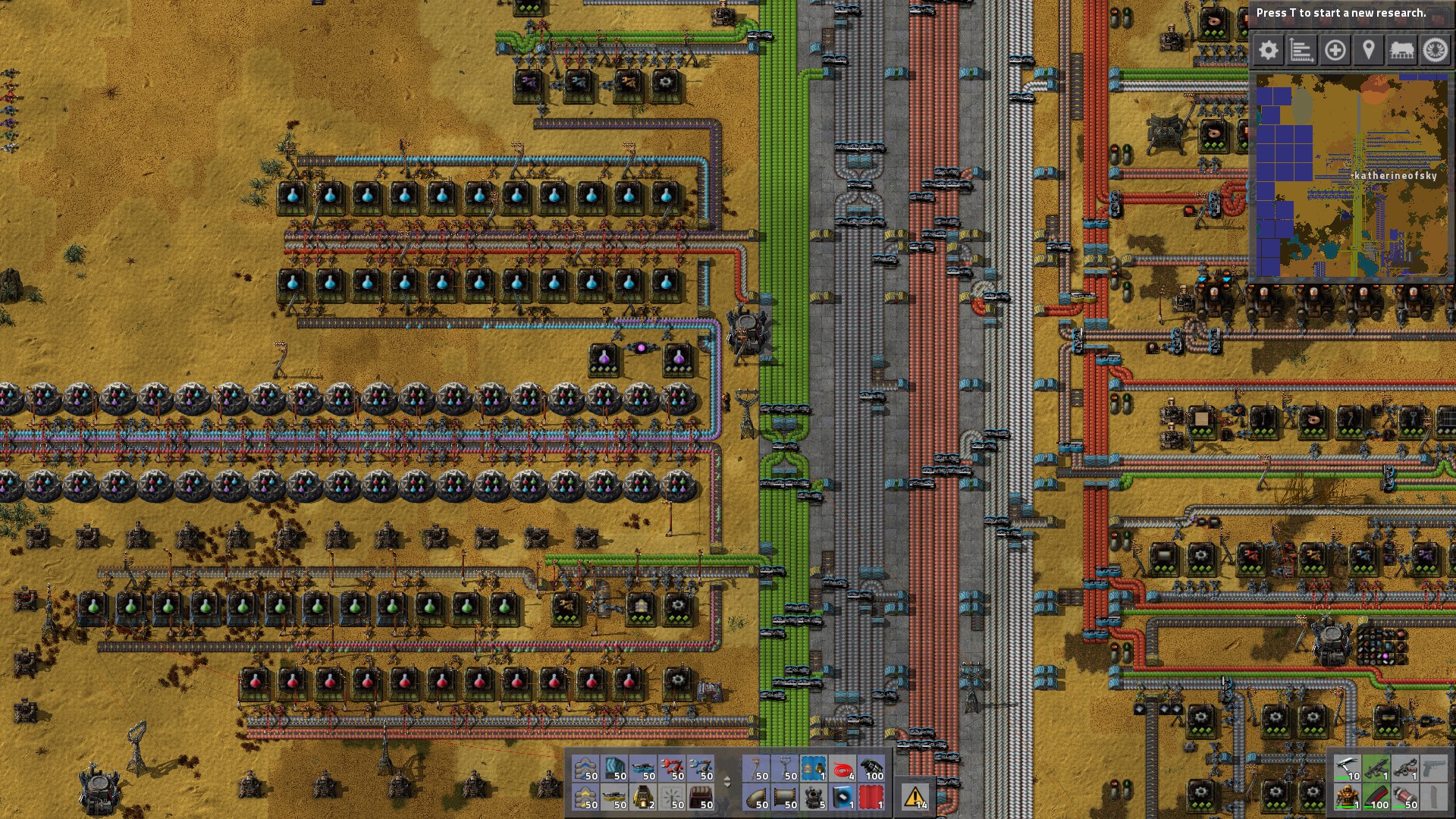

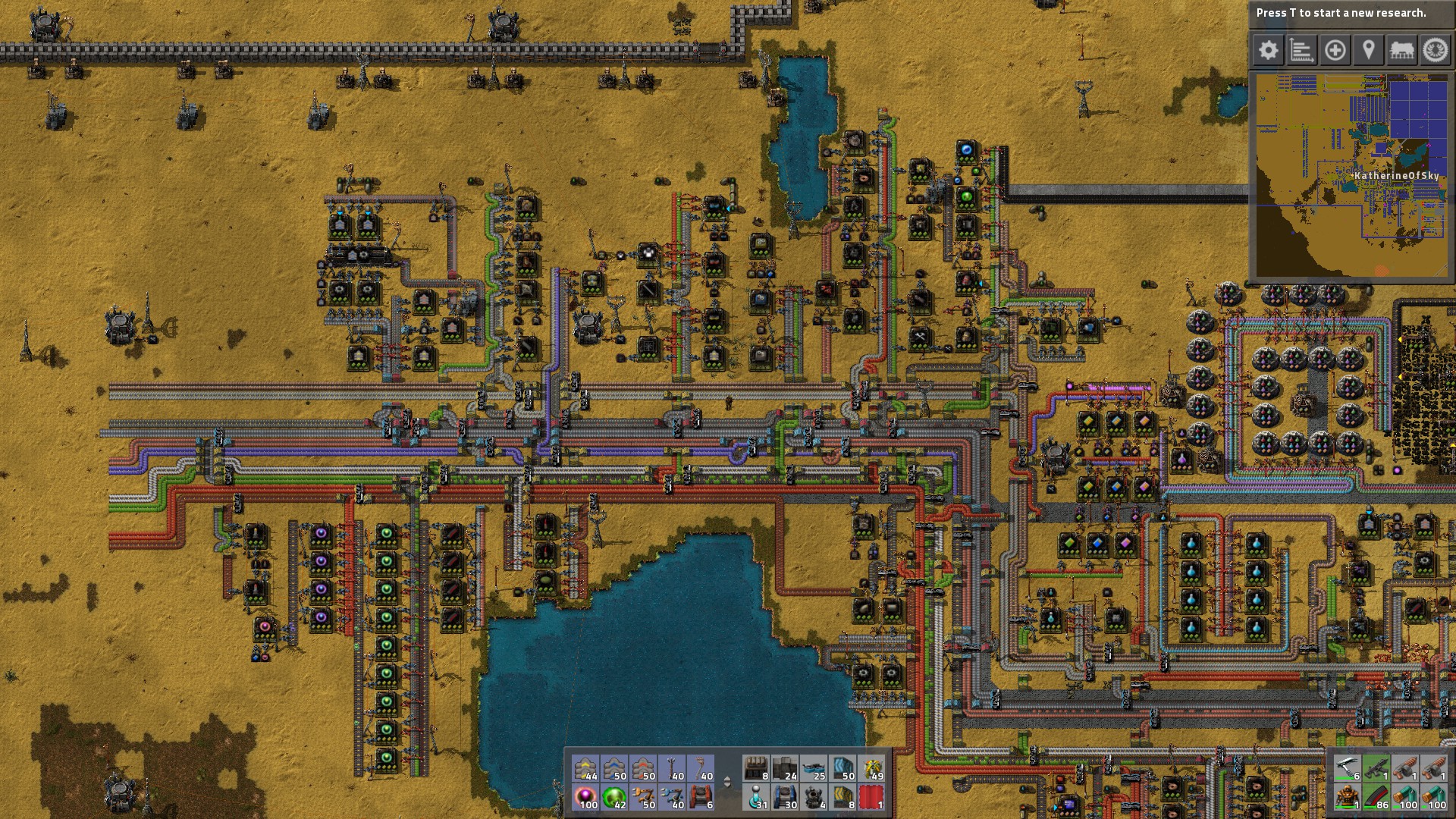

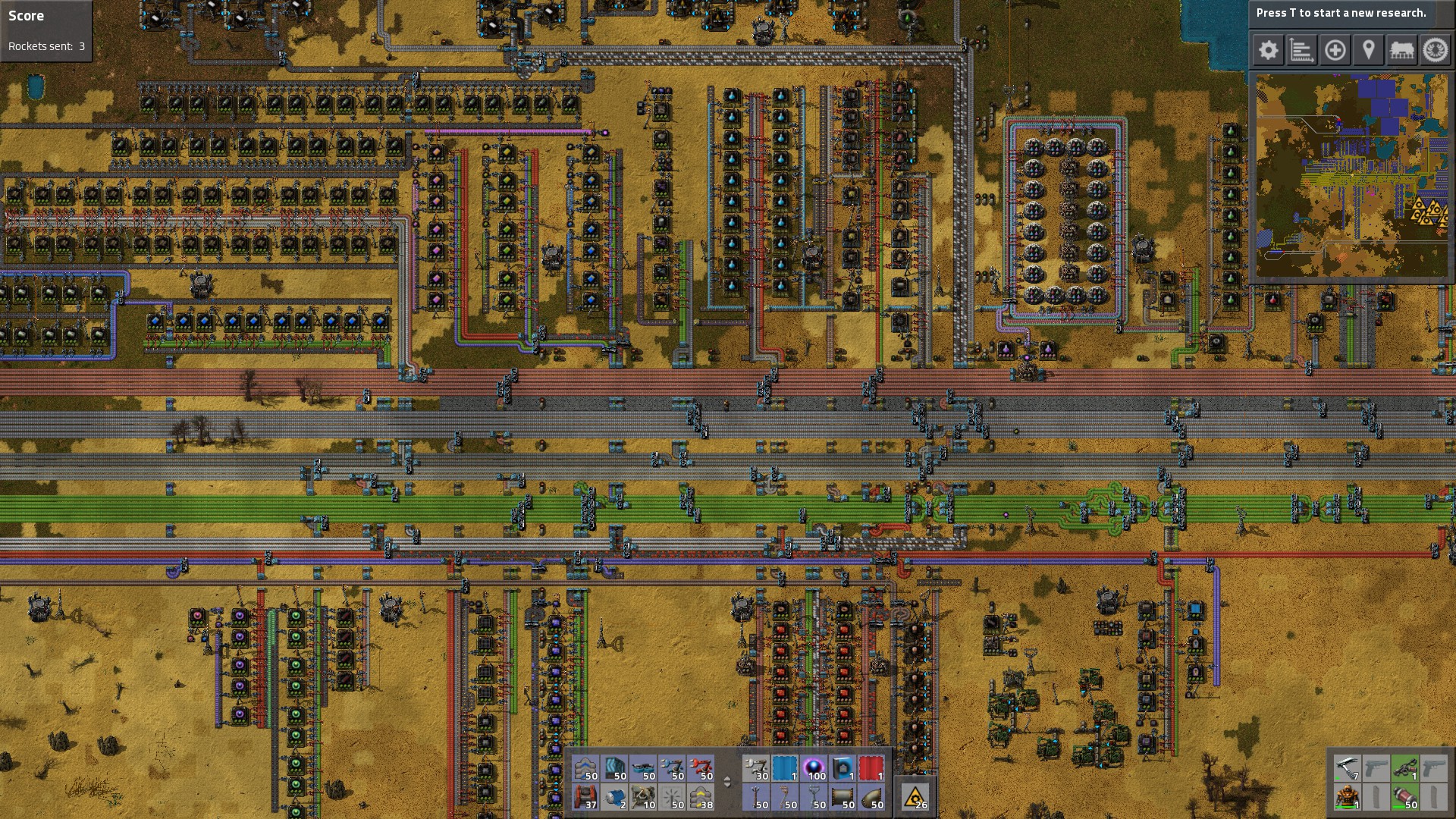

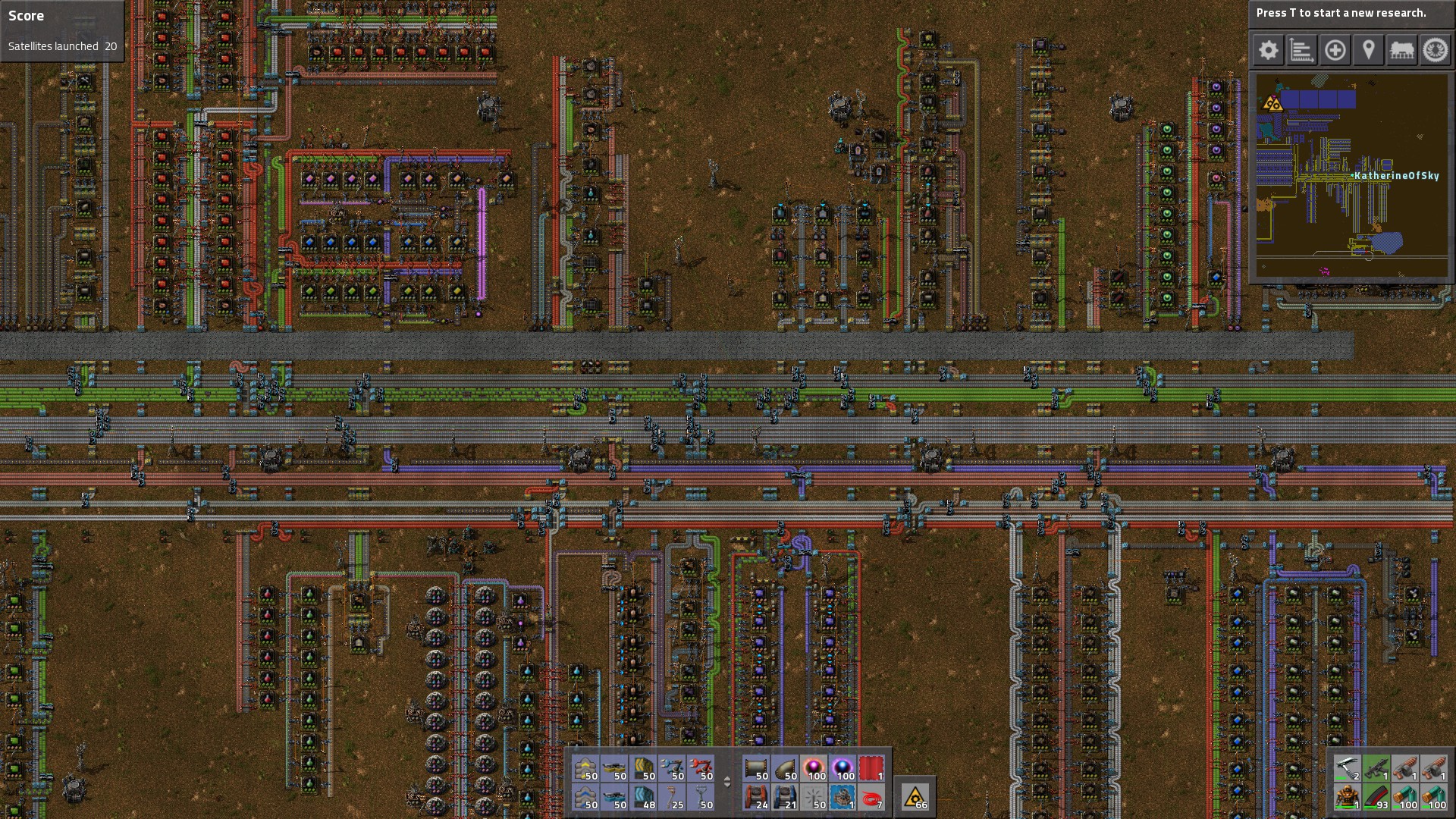

Over time, I've built a large number of factories... here are some examples of Main Bus systems that I've used.

One of the first factories in which I used a Main Bus system. I had very few lanes of product in comparison to what I do now.

My first Ribbon World! A thinner bus structure was desired because of the space limitations. The map was 100 tiles high x infinite wide.

My first speed run factory. I lost a lot of time having to curve around the forest! However, I got a time of 7:02:00 on the first run, yay!

Handcrafting Challenge factory. Definitely teaches you how to build efficient structures for everything in the game!

Another horizontal bus in my "Harsh North" factory.

My "Crunchy Desert" factory. I purposefully built a north/-south bus because I kept getting caught up in horizontal ones! :-)

Tips

Why These and Not Those? Copper Cables: While they are high in demand for green circuits, they are used in almost nothing else. They are also inefficient to belt -- 1 copper plate makes 2 copper cables, inflating the need for belts by two-fold! Far better to make these locally as needed.

Gears: While the ratio of iron plates to iron gear wheels is advantageous ratio-wise, (2 plates makes 1 iron gear wheel), I've found (through real experimentation) that it is much more efficient to make Gears locally. In place they are used sparingly, 1 gear factory provides more than enough for an assembly line, and they can be placed such that the iron comes on half the assembly line, and the gears are placed on the other half. (Many products require both iron plates and gear wheels)

The places that gears are needed are in great quantity, such as belt manufacturing arrays, it's easier to make them onsite by diverting iron plates in. Gears via Main Bus always seemed lacking, even if I put extra lanes in.

Resources

Additional referece for all that is Factorio:

The Factorio Game Forums[forums.factorio.com] - The officical game forums. Good place to find discussions & mods.

Factorio Wiki[wiki.factorio.com] -- LOTS of helpful information here. Official game site.

Referencio[referencio.info] -- Lots of information about ratios, etc.

Factorio Game Guide[guide.factorio.com] -- Great tutorials, again, an official source.

Factorio Cheat Sheets[docs.google.com] -- Very clear illustrated guide to ratios, items/per second, etc.

Factorio Data[factorio.rotol.me] -- Excellent place for finding which components go into what. Also look up ratios for nearly everything in their Factoratio section.

Finale

Thanks to everyone who shares their ideas on the forums & YouTube! Sharing makes us all stronger and more inspired to come up with new ideas!

Please check out my Let's Plays and Tutorials on YouTube, if you want to see these methods in action!

I welcome all comments & questions.

(If you want a more chat-friendly environment, you are welcome to come to my discord server: https://discord.gg/ybyyaSE)

Source: https://steamcommunity.com/sharedfiles/filedetails/?id=754378586

More Factorio guilds

- All Guilds

- Before The Bus

- Factorio Compact Designs

- Space Age:

- Sandbox mode in 2.0

- How to speed up "Loading Sprites" when game boots up

- Seamless Space-Saving Blueprints (18x18 tiles)

- Rails Signaling for Dummies

- Factorio: Observations, Tips, Tricks, & Efficiency

- Factorio Guide 1061